Sustaining Engineering: The Key to Improving Products and Processes

At OnLogic, innovation is one of our core values. The engineering team is constantly working to push the envelope to create the most versatile systems while packing increasingly powerful processing into compact, often passively cooled, machines (see the Helix 300 and Karbon 400 as examples). However, we also know that being innovative doesn’t stop once a product launches. As part of our focus on continuing to provide the best computing solutions in the industry, we implement sustaining engineering.

What is Sustaining Engineering?

Sustaining engineering focuses on the maintenance and continuous improvement of products through their entire lifecycle. In industries that design systems intended to have a long lifecycle, like industrial and embedded computing or medical technology, sustaining engineering enables ongoing design improvements based on internal team and external user feedback, as well as applicable industry developments and innovations.

Sustaining Engineering in Action

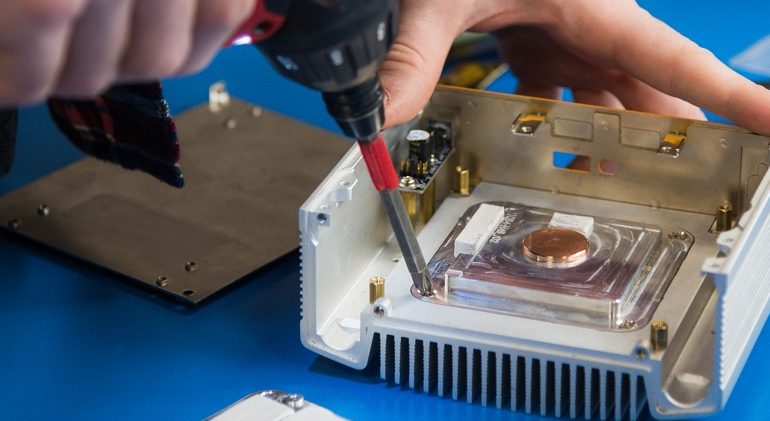

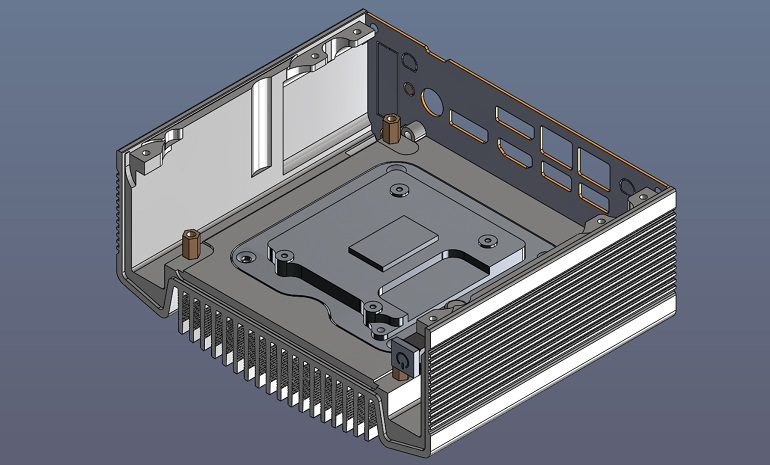

An example of where sustaining engineering can drive innovation within OnLogic’s portfolio is a recent update to our ML100 fanless computer. The ML100 utilizes small form factor Intel NUC boards and AMD 4×4 boards. These motherboards provide high processing power in a compact package that’s cooled passively, without the use of a fan or openings in the case. In order to accomplish this, the motherboards are attached to the chassis and then screwed down onto an aluminum heatpipe to conduct heat to the outer heatsink; this design is key to fanless cooling.

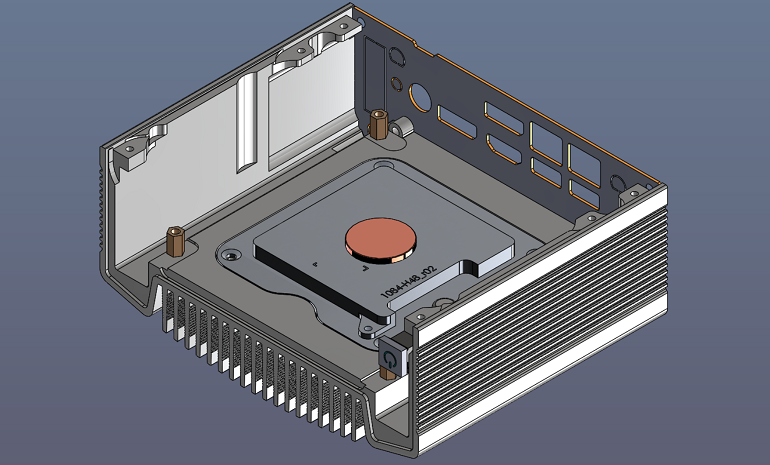

In assessing the functionality and manufacturing of the ML100, the team identified an opportunity at this critical thermal junction. We were able to eliminate the screws and add a pressed-in copper slug. With the higher thermal conductivity of copper, the system is able to maintain the industrial thermal performance that customers have come to expect.

The benefits of this change are numerous; the time to assemble the system is reduced, as well as the complexity of the overall cooling assembly. In addition, the elimination of threaded screws reduces scrap rates, as there are fewer parts to break. For customers, this change presents no impact; these high power systems will continue to function in demanding environments. For OnLogic, this change means we can produce these systems even faster, further reducing our already short lead times.

- The previous version of the ML100 heatpipe.

- The new version of the ML100 heatpipe.

The Benefits of Sustaining Engineering

Sustaining engineering can also drive innovation, as the lessons learned from the process of continuous improvement can provide new insights for future developments. For example, the learnings from the ML100 heatpipe redesign can be applied to future system developments, helping us improve our processes and serve our customers more efficiently.

Improvements being identified and addressed by sustaining engineering aren’t limited to mechanical chassis changes. Other ongoing projects include improvements to packaging in order to reduce waste, packaging time, as well as to improve the unboxing experiences for customers.

Overall, sustaining engineering at OnLogic is another way that our engineering team strives to constantly improve our ability to best support our customers. By innovating on our current portfolio, in addition to new products, and applying lessons learned from our latest developments, the team is consistently seeking new ways to provide the highest quality products possible. For more on what the engineering team at OnLogic can do for you, check out our custom engineering services or explore what’s new from the OnLogic team.

Get the Latest Tech Updates

Subscribe to our newsletters to get updates from OnLogic delivered straight to your inbox. News and insights from our team of experts are just a click away. Hit the button to head to our subscription page.

Share

More Articles

OnLogic Industrial Computers

Discover OnLogic's multitude of industrial computers that will help you to advance your IoT project

Learn more at OnLogic.com

OnLogic Industrial PCs: Designed to last. Built to order. Delivered in days. Visit our online store at OnLogic.com