ETL Listed vs UL Listed: A Guide to Understanding Safety Certifications

There are a wide range of processes and procedures in place to ensure that all OnLogic products are safe. This includes testing to both nationally and internationally recognized standards. Tiny logos representing UL Listed, ETL Listed, and CE Certifications (just to name a few) have become commonplace on all manner of technology products. But what do these safety marks really mean? What can you determine from them? And what does it take for manufacturers to earn and keep them?

The first important thing to know is that these certifying marks come from a Nationally Recognized Testing Laboratory, or NRTL.

What is an NRTL?

The Occupational Safety and Health Administration (OSHA) is the US organization ultimately responsible for ensuring safe and healthful working conditions. Part of what OSHA does involves setting and enforcing safety standards for products used by businesses and consumers. To help OSHA in this effort, a Nationally Recognized Testing Laboratory (NRTL) program was established. As OSHA puts it, the NRTL program:

“Recognizes private sector organizations to perform certification for certain products to ensure that they meet the requirements of both the construction and general industry OSHA electrical standards. Each NRTL has a scope of test standards that they are recognized for, and each NRTL uses its own unique registered certification mark(s) to designate product conformance to the applicable product safety test standards.”

OSHA is part of the US Department of Labor. However, each test lab in the NRTL program also strives for accreditation from the applicable “OSHA-like” organizations throughout the world. This enables them to serve companies seeking certifications that will allow their products to be sold internationally.

How are safety standards established?

Each testing lab has their own proprietary set of testing procedures. These procedures are built on “rules” written by the International Electrotechnical Commission (IEC). As the IEC puts it:

“IEC Standards ensure the performance, reliability, efficiency and safety of electrical and electronic systems and devices. They provide a common language and terminology that experts can use when developing standards for technology.”

Testing labs around the world build their testing processes from these IEC standards and then, commonly, brand their version of the standard using a proprietary mark to establish that their lab was responsible for performing the testing. As you can see on the OSHA website, there are quite a few NRTL labs around the country and many others responsible for international and regional testing, but some of the more common marks applied to products by the various NRTLs include UL, ETL, SGS, CSA, BV, and TUV.

In creating their own “branded” version of the IEC testing rules, individual labs will commonly:

- Subtract any regional differences that don’t apply to their particular geography

- Add any regionally specific items that may be applicable

- Attach their own company policy related to ongoing surveillance of adherence to certification standards

The last point is often overlooked, but vital to keep in mind. For companies looking to have products tested and listed, as well as users interested in ensuring that the products they purchase today meet the applicable safety standards, it’s important to understand the role that ongoing surveillance plays in ensuring products maintain compliance to safety standards.

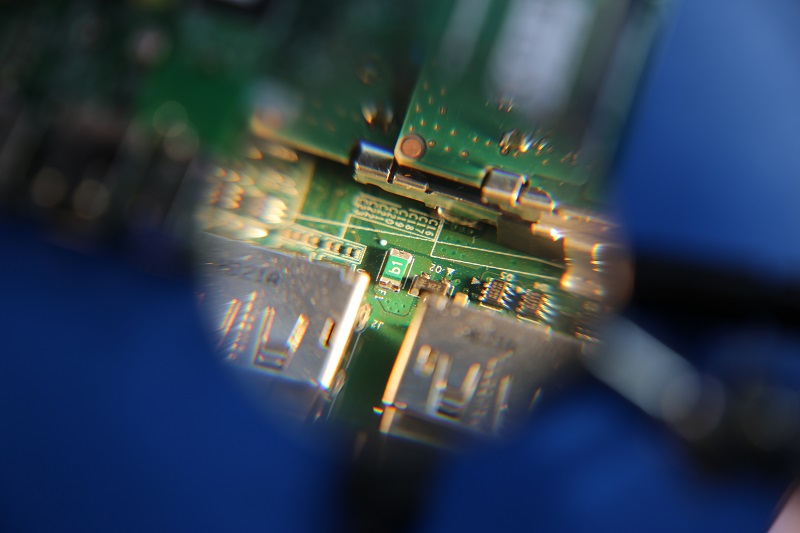

This tiny fuse protects the 5 & 12V outputs of a COM port. The fuse meets UL and IEC requirements for current limiting devices.

The importance of safety standard surveillance

Along with the completion of a safety assessment and the right to use the corresponding mark of a given testing lab (UL Listed, ETL Listed, etc.), companies seeking safety marks for their products agree to regular check-ins by the NRTL surveillance team to ensure that products continue to adhere to the established standards and are compliant with component traceability requirements. Often overlooked by users, it’s not uncommon for product certifications to be withdrawn by a lab during ongoing surveillance efforts. This means that a product that has previously been tested and listed may no longer qualify to carry the associated NRTL mark.

Fortunately, NRTLs are required to keep, and companies are required to make public records of the products they have tested and listed. This allows users to verify the current standing of any product they’re considering. In addition, users can confirm that a given factory is approved to manufacture a particular product type.

In addition to differences among NRTLs in the US, surveillance standards also vary by region. As an example, the CE Mark, representing The Conformite Europeenne, is required on many products being sold in the European Union. As a global company, OnLogic products also carry the CE Mark. However, it’s important to note that the CE certification process does not mandate an ongoing surveillance element for most product categories.

What is UL Listed?

Given all of the above, what can you learn from the presence of a given lab’s mark? In the case of the UL Listed Mark, a product being UL Listed means that it has been tested and verified to meet the “branded version” of IEC safety standards as defined by Underwriter Laboratories (UL), and that it is subject to quarterly product surveillance. Underwriter Laboratories is a member of OSHA’s NRTL program and has been around for more than 100 years.

What is ETL Listed?

ETL stands for Electrical Testing Laboratories, the certification division of Intertek Testing Laboratories, who are also part of the NRTL program and provide assurance, testing, inspection, and certification services for a huge range of industries. Founded in 1896 by Thomas Edison, Intertek has 30+ offices and laboratories around the world.

Like UL, ETL tests to the same standards as all of the NRTLs and apply their ETL Listed mark to the products they test. Ultimately, there is little difference between UL and ETL (or any of the other participants in the NRTL program). So what is the difference between UL Listed and ETL Listed? Aside from the marks they apply to products after testing, there are also slight differences in the surveillance programs they operate.

The dangers of using products without a safety listing

Now that you understand the differences (or relative lack thereof) between UL and ETL, why should you care about ensuring the products you use have been tested and listed by an NRTL or other international testing organization? As you might expect, it all comes down to safety.

Safety in the world of computing

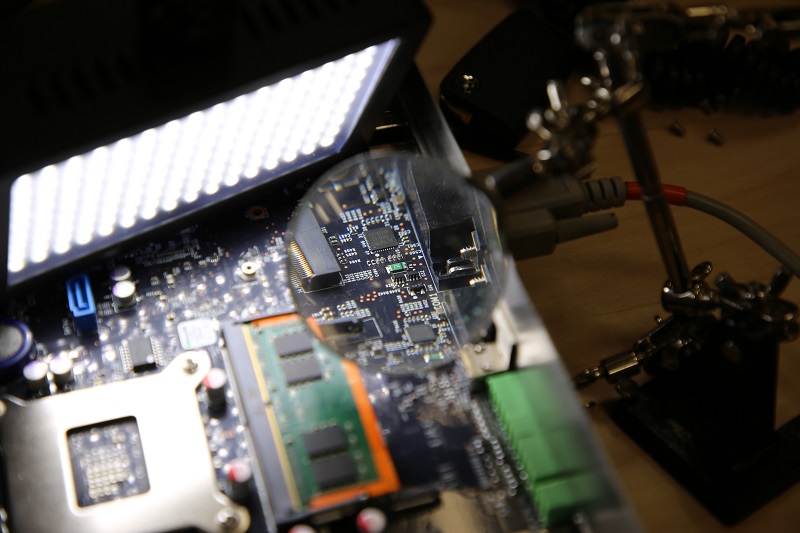

To ensure safety in the world of computing, plastics need to be self-extinguishing, connectors need fuses, wires need fire rated materials, systems require additional thermal protections, and proper power supply safety features must be present to prevent lethal currents to users. NRTLs will carry out fault testing by shorting fuses to make sure they work, intentionally overheating units to make sure they turn off safely, stalling cooling fans or other moving parts to ensure that they don’t cause a fire, and simulating a wide range of other extreme “real world” scenarios that a user could potentially encounter. Once the NRTLs test these elements, they monitor them through ongoing surveillance.

Extending the importance of safety testing even further, a lot of recent media coverage has highlighted safety concerns with everything from smart doorbells to lower end USB charging cables and power adapters. The NRTL targets their safety assessments and surveillance at preventing dangerous configurations by assuring safety features are working properly. They also ensure that the raw materials are from approved and verified suppliers, including clear transparency throughout the entire production process.

Why you should look for safety marks

It’s a fairly common myth that the 5V charging power passing through a USB charging cable isn’t capable of igniting a fire. A USB port with no fuse, or one that is paired with a USB cable without a fire rating or with undersized conductors, can cause the wiring within the cable to essentially become a ‘glow wire heater’. That means that any combustible materials around it could catch on fire. Situations like this are why it’s so important to make sure that your bargain USB charging cables carry a safety mark.

ETL Listed vs UL Listed – the bottom line

The bottom line on ETL Listing and UL Listing is that while both marks represent very similar things, UL has become one of the more recognized and referenced product safety marks. Both UL and ETL testing procedures are accredited by OSHA to issue safety marks, as well as many of the other international organizations responsible for establishing safety standards. Utilizing a product that bears either mark will help to ensure that what you’re installing in your home or business won’t present a safety hazard. At OnLogic, we offer products that are UL Listed and ETL Listed.

OnLogic’s regulatory team works closely with a wide range of international testing laboratories, including both UL and Intertek, and can help answer any questions you may have about product safety standards and certifications. We have years of experience with safety testing and listing. If you need to ensure your computer complies with any required safety standards for your application, we can help! Learn more about our certification services here.

This blog was originally posted on February 8th, 2021. It was updated for content on April 18th, 2022.

Get the Latest Tech Updates

Subscribe to our newsletters to get updates from OnLogic delivered straight to your inbox. News and insights from our team of experts are just a click away. Hit the button to head to our subscription page.

Share

More Articles

OnLogic Industrial Computers

Discover OnLogic's multitude of industrial computers that will help you to advance your IoT project

Learn more at OnLogic.com

OnLogic Industrial PCs: Designed to last. Built to order. Delivered in days. Visit our online store at OnLogic.com