There are many types of access control all over our modern world for security purposes to prevent unauthorized access. These include, of course, passenger checkpoints at airports and access gates to the tracks of subway stations. Access gates and turnstiles are also used in parking garages, in front of public facilities and event locations or at sports centers.

One of the most important manufacturers of vehicle and pedestrian access gates for a wide variety of applications is Magnetic Autocontrol. The company is based in the south of Germany, in Schopfheim, at the edge of the Black Forest. Worldwide, the company has 32 subsidiaries and more than 600 employees. Since 2012, Magnetic has also been a member of the Italian FAAC Technologies corporate group. The executive headquarters, the technological and managerial heart of FAAC, is located in Bologna, Italy, but the group boasts a huge presence abroad, where it develops most of its business with both production sites and commercial operations.

With consolidated sales of more than 600 million EUR and 53 companies in 5 continents, FAAC employs over 3,600 individuals across the globe.

At their development center more than 30 employees work on hardware and software for innovative products and customer-specific solutions. An in-house testing and standardization department ensures high quality, user safety and compliance with the relevant regulatory requirements.

The challenge: efficient and safe airport passenger access management

The name Momentum® describes the force of an object that is in motion. This refers to the increased momentum that the end application brings to airport operations. After all, passengers demand a speedy process and a convenient check-in experience without lengthy lines.

When developing the new Momentum® access control series for use in passport control at airports, Magnetic Autocontrol faced a number of challenges. The end customer's goal was to install as many passenger control gates within minimum space in order to efficiently handle the high traffic throughput of travelers.

Check-in situation at an airport

Many details for the end customer – hardly visible for passengers

The specifications of the end customer were strict. In order to fit as many lines as possible, the enclosure for the access control system needed to be as thin as possible.

Accommodating a computer to control the access control system in the enclosure became a challenge. On one hand, a powerful computer was needed, but on the other hand, it had to be as compact as possible. Furthermore, high reliability was paramount. When used at an airport, a shutdown due to system failures or repairs could quickly escalate to chaos and unsatisfied passengers. Moreover, security of hardware supply – especially given global supply chain issues – was an important factor. And of course, an affordable price also played a role.

A compact OnLogic industrial PC opens the gate

Magnetic Autocontrol decided on the ML350G-10 fanless industrial PC. Deployed in the mGo and mPass products in the Momentum product line, this compact unit processes data from the passport readers. The computer compares the biometric data from the passports with information from facial recognition cameras and barcode scanners used to read boarding passes. The data is forwarded to a database provided by the airport operator for authentication and authorization. If the passenger data matches, the access gate opens and passengers can pass through.

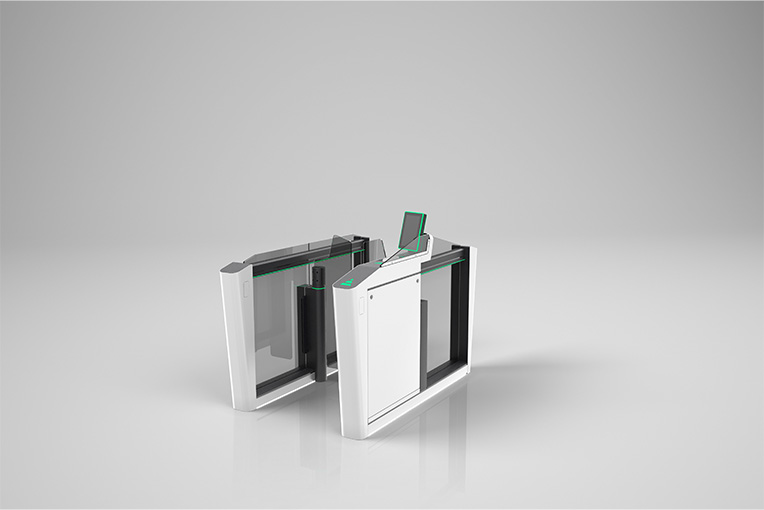

The passenger control system mGo by Magnetic Autocontrol

An industrial PC in passenger control – invisible efficiency

With its low 1.5" profile, the ML350G-10 fits perfectly into the passenger control system unit. The design on this model is fanless, which makes it quiet, clean and ultra reliable. This minimizes disruption from frequent maintenance. Reliable operation is also supported by 4G LTE connectivity for failover protection. As a result, passenger controls run smoothly and efficiently.

The mPass passenger control system consists of very slim lines for optimal use of space.

Why OnLogic

“During the project, we appreciated the constant good communication by OnLogic. Even on tough issues like the current supply chain challenges. We were always informed early and kept up to date.”

- Timo Rauer, Portfolio Manager Pedestrian Gates

This was not the first collaboration between Magnetic and OnLogic. It was the positive experience that they had in smaller projects that enabled the consideration of OnLogic for the Momentum product line.

“I'm responsible for the selection of the components and I can highlight the excellent support on all technical issues. The team at OnLogic has been very responsive to our requirements. They were always committed to finding the best possible solution for us as a customer.”

- Olaf Wittich, Hardware Development, Electrical Design