Helping Creative Electron Capture The Otherwise Invisible

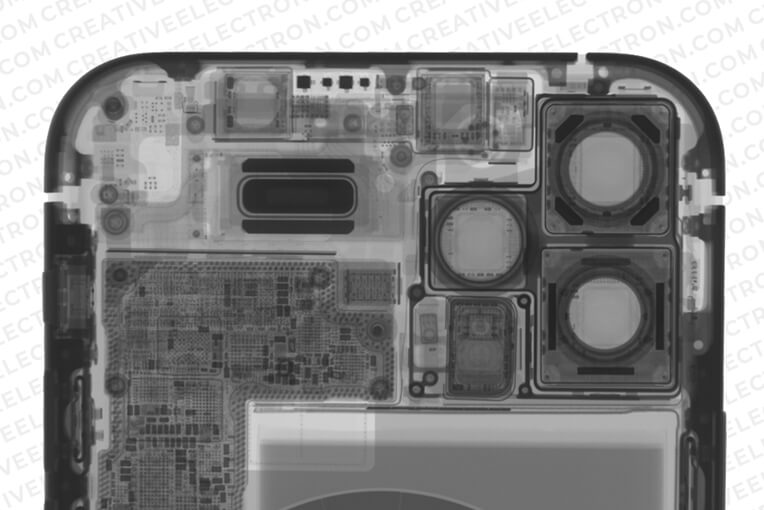

When it comes to product quality, often it's what you can't see that makes the biggest difference. From counterfeit and fraud detection, to advanced quality control for manufactured products, Creative Electron, Inc. specializes in advanced X-ray inspection systems. Their systems provide a clear view of what's below the surface of a huge range of items, providing manufacturers and consumers alike a clear view of what's inside everything from precious works of art to the latest cell phone models. Capturing the unique images that Creative Electron specializes in takes specialized camera technology and cutting edge software, all backed by powerful computing.

Creative Electron manufactures a wide range of X-ray cabinets meant for both ongoing inspection or on-demand imaging.

Founded twelve years ago as a research and development company that worked with the US government, over time Creative Electron's application focus narrowed to radiation and, more specifically, X-ray inspection. After developing software for the field, they began designing and building their own X-ray inspection solutions. Today they are the largest manufacturer of X-ray inspection cabinets in the United States.

It's What's Inside That Counts

Creative Electron builds a wide range of X-ray cabinets to suit the varied needs of their customers. The one constant through all of their designs is a need for exacting repeatability and reliability. The highest standard of product quality is what Creative Electron's business is built on, so it's only natural that this same commitment to quality would extend to the X-ray devices they create, which is why they turned to OnLogic for the computing power they needed to develop their latest systems.

Creative Electron manufactures a wide range of X-ray cabinets meant for both ongoing inspection or on-demand imaging.

“A lack of stability and customization options were the key issues that we were running into with prior hardware solutions. Lower tier computing systems are not designed to handle the processing requirements, constant operation and working environments our customers frequently place our systems in. We also work on projects with the government and high security facilities, so having the ability to design a system without Bluetooth or Wi-Fi, or with a removable hard drive, for example, were key considerations for us, and OnLogic makes all of those options possible.”

- David Kruidhof, VP of Sales at Creative Electron

Creative Electron X-ray system.

The OnLogic computers inside Creative Electron's X-ray systems allow operators to control the X-ray source, detector, and all other movement systems. They also have the ability to run processor and GPU-heavy applications, like AI and deep learning via powerful GPU-assisted computing.

The configurability and customization capabilities of OnLogic systems is critical to Creative Electron because their X-ray systems are similarly flexible. Some customer applications call for more image processing power, while others have accessible port restrictions to ensure system security. Other Creative Electron customers install their systems in environments that would challenge, or even disable, less rugged equipment.

“The X-ray inspection challenges that OnLogic hardware enable us to solve are virtually limitless. We commonly use OnLogic hardware for our most rugged applications, and they're consistently able to provide us with reliable computers at a reasonable price. When systems need to be running 24/7 to keep up with customer demands, we need more than a standard desktop box. Processing high-resolution X-ray images through machine vision algorithms and artificial intelligence, while managing the hardware and uploading all the final data to a server, is a typical use-case scenario, and that demands a very powerful, reliable piece of hardware.”

- David Kruidhof, VP of Sales at Creative Electron

According to David, providing a stable, reliable computer that controls the system has significantly decreased downtime for Creative Electron customers, leading to fewer service calls to the Creative Electron support team. The high-powered processing that the OnLogic systems provide also allows users to process data faster than Creative Electron's previous solutions, making overall X-ray device operation more efficient and increasing scan throughput.

What's Next for Creative Electron?

The team at Creative Electron is always looking toward other industries that can benefit from adding X-ray inspection into their quality control, failure analysis, or material handling processes. As they continue to develop new solutions to emerging challenges for their customers, they expect OnLogic hardware to be a key component in their next generation of X-ray cabinet solutions.

“Working with OnLogic has been smooth and seamless. They provide us with what we want when we want it without unnecessary hurdles or delays.”

- David Kruidhof, VP of Sales at Creative Electron