What is SCADA Automation and How is it Used?

Supervisory Control and Data Acquisition (SCADA) is a combination of hardware and software used for industrial automation. SCADA automation allows users to:

- Supervise and control industrial processes both locally and remotely

- Acquire, process, and record data

- Interact with local machinery through HMIs (Human Machine Interfaces) and PLCs (Programmable Logic Controllers) to communicate with the SCADA system

When it comes to SCADA, one of the most common questions is, “What is SCADA and how does it work?”. SCADA systems allow companies to make smarter decisions, improve efficiency, and minimize downtime. SCADA is used across a variety of industries and is commonly found in manufacturing, automation, oil and gas, and wastewater applications.

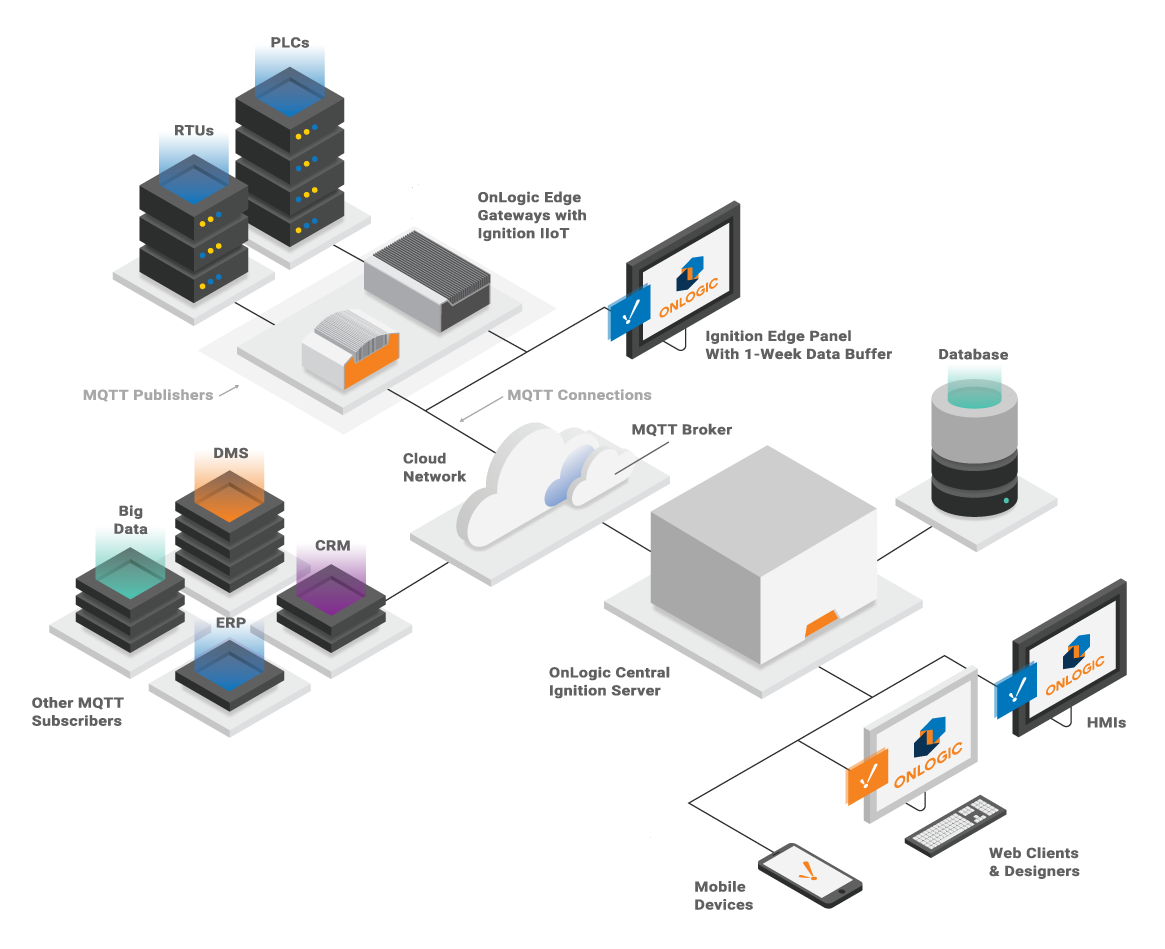

SCADA systems work by connecting local sensors, devices, and PLCs – which collect datasets, known as Tags – to an onsite server or remote/virtual machine. Data can also be saved to a historical database so that it can be analyzed later. Users interact with the SCADA system to control processes remotely or through operator workstations, HMIs, or directly on the SCADA server.

SCADA Brings Visibility to Make Informed Decisions

A SCADA system brings more visibility to users to make informed decisions. For example, a plant supervisor at a soft drink bottling plant wants to be able to view all production lines, improve uptime, and reduce downtime based on the plants’ current performance. In order to accomplish this, they need tags from each station in the production process. With a SCADA system, the line supervisor would receive an alert when a filling station’s nozzle pressure has gone down by 20%, increasing cycle time by 5 seconds. The line supervisor can quickly send a technician out to replace the damaged nozzle and bring the line back up to normal capacity. Using a SCADA system, the plant supervisor was able to diagnose and fix the issue before it led to process bottlenecks (no pun intended) in later stations, or brought the whole line down due to a critical part failure.

Questions to ask when considering using SCADA

What am I looking to accomplish?

- A SCADA system can meet a wide variety of needs, so it is important to define your project goals and KPIs from the start. Beyond plant control and supervision, do you want to: Reduce costs related to maintenance? Reduce downtime? Improve plant reporting?

What machinery will I need to monitor in order to accomplish my objectives?

- Am I installing new machinery or equipping existing machinery? Can I communicate directly with the machinery via an industrial protocol like Modbus TCP/IP or do I need to integrate PLCs to communicate with the machinery and sensors?

What type of industrial PC hardware will I need to deploy?

- Do I need a computer that can run 3+ monitors in the control room for overall plant supervision? Do I need an all-in-one panel PC for an HMI so my production line operators can interact with machinery directly on the line? Do I need a rugged Edge computer with 4G LTE modem to send data back over MQTT from my field site?

Who are my stakeholders for this project?

- Engineering, information technology, operations, and other relevant departments should be involved to ensure a smooth integration.

Do I have the right people on my team to support a SCADA system integration?

- If this is your first time doing a SCADA integration your company might not have the necessary knowledge base to support it. Many end-users of SCADA systems work directly with an approved solutions integrator to tailor a solution for a given project.

Leveraging Ignition for SCADA

OnLogic has partnered with Inductive Automation to bring together hardware and software in a single package. Inductive Automation’s SCADA solution, Ignition, is a platform that connects all the devices on your plant floor. It is hardware-agnostic so you can use the combination of PLCs, databases, and PCs that you need. Ignition SCADA software also has powerful built-in visualization and reporting tools so decision makers can make the right decision at the right time. Inductive Automation also has an integrator program, which presents the opportunity to work with certified integration specialists in your region to create a complete solution that is right for you, without needing to hire your own in-house specialist.

One of the inherent risks of IIoT (Industrial Internet of Things) applications is that systems must have an internet connection to function properly. Inductive Automation has solved this with their Ignition Edge software. Ignition Edge allows systems to act independently until a network connection is reestablished. There are a number of versions of Ignition Edge, the most common being:

- Edge Panel which allows you to run a local HMI autonomously from the rest of the network

- Edge IIoT to facilitate data transfer via the lightweight MQTT protocol

- Edge Compute to utilize REST APIs, python scripting, or run Sequential function charts

Which version, or combinations of versions, that’s right for you will depend on your project needs. Read more about our industrial automation solutions here and if you are ready to configure your own solution, check out options here.

How SCADA could be used for Oil and Gas Projects

Why use an Industrial PC as part of your SCADA Solution?

One of the most common motivations we hear from customers who are considering industrial hardware, is that they can’t handle the downtime caused by unreliable IT equipment. American Woodmark, for example, chose OnLogic’s industrial PCs to replace their existing desktop towers because of the time lost vacuuming out debris from CNC machinery. Downtime dropped to less than 1% when they made the switch to a fanless solution that was built to perform in a manufacturing environment. Learn more about the project and the benefits of fanless computing in this customer story.

The deployment environments for SCADA projects vary as much as the industries they serve. OnLogic’s line of Ignition Edge solutions are tailored for deployments across a wide range of SCADA applications. We offer solutions that are resistant to dust, temperature, shock, vibration, and variable input power. Systems are built to order and tailored to your project. An internal 4G LTE modem for remote communication, PoE+ ports to run a camera, or any other number of options are available across our hardware platforms. Combine our hardware with Ignition Edge to further increase uptime, decrease downtime, and improve operational efficiency.

What if I already use AWS Cloud services?

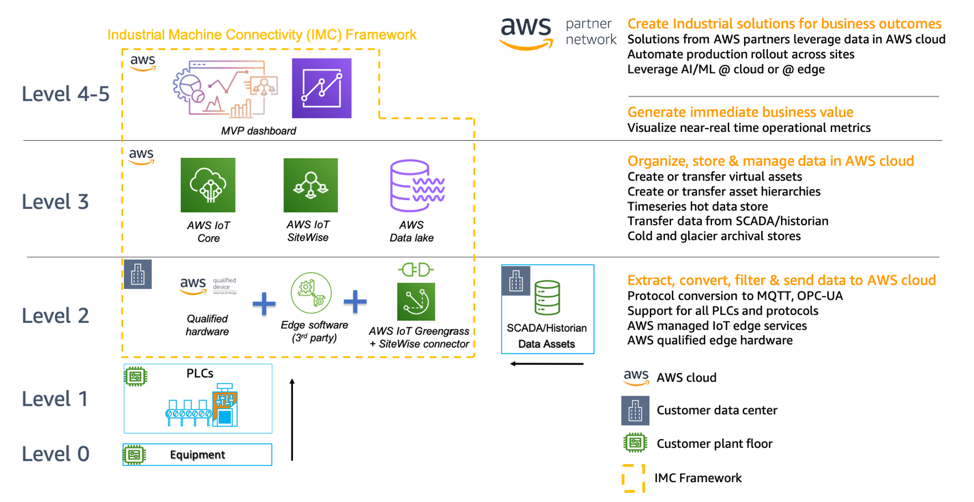

OnLogic and Inductive Automation have collaborated with Amazon Web Services to leverage the powerful tools that AWS offers. Use AWS IoT Sitewise, S3, and Kinesis to collect, analyze, and store data. Data can be sent back to Ignition for use in its powerful reporting tools or sent to AWS analytical services to pull insights directly from the cloud. Learn more about AWS connected factory solutions and the Industrial Machine Connectivity (IMC) kit in this article. You can also check out this video that describes how Volkswagen is leveraging AWS for their smart factory initiative. Contact us and we can help you leverage this tool to start prototyping quickly.

Map of how the IMC kit components relate to ISA95 levels and what capabilities are enabled at each level. Image by AWS.

Whether you need to deploy SCADA automation in a small factory, or monitor hundreds of remote devices across thousands of miles, OnLogic has hardware solutions for you. Explore our online store, or contact us today to get started!

Editor’s Note: Inductive Automation has ended their Ignition Onboard program. Ignition licenses must now be purchased directly through Inductive Automation. While the IGN versions of our solutions are no longer available, our computers remain a great fit for use with Ignition software. Explore our recommended hardware here.

We originally posted this blog on August 28, 2020. We updated this blog on April 15, 2022.

Get the Latest Tech Updates

Subscribe to our newsletters to get updates from OnLogic delivered straight to your inbox. News and insights from our team of experts are just a click away. Hit the button to head to our subscription page.

Share

More Articles

OnLogic Industrial Computers

Discover OnLogic's multitude of industrial computers that will help you to advance your IoT project

Learn more at OnLogic.com

OnLogic Industrial PCs: Designed to last. Built to order. Delivered in days. Visit our online store at OnLogic.com