What is a PLC? How does it Work?

It is impossible to imagine modern industrial automation without PLCs. But what is a PLC and how does it work? In this article, we will explain the fundamentals around this technology.

What is a PLC?

A programmable logic controller (PLC) is a computing device used in automation and manufacturing environments. It controls different electro-mechanical processes based on inputs and specific rules.

A brief history of the PLC

Engineer Richard E. Dick Morley is often referred to as the father of the PLC. In 1968, he developed the first semiconductor-based solution he called the “Modicon” (MOdular DIgital COntroller). It was designed to replace hardwired relay systems which had a tangle of wires and consequently, were difficult to update.

With their introduction, PLCs reduced the time, cost and effort needed to update a process. As a result, industrial automation and communication between devices became easier.

Digital rather than cable chaos

In contrast to electromechanical controllers, PLC programming is digital. Therefore, a PLC can handle more complex control tasks. If a change is necessary, the program can simply be rewritten.

In addition, the program can be copied, used as often as needed, and supplemented with comments and documentation. This makes it easier to modify programs at a later point of time.

What comprises a PLC?

A PLC consists of the following:

- CPU

- Inputs (e.g. from the sensors)

- Program

- Outputs

A PLC can be realized in different ways. It can be a stand-alone device or used as a plug-in card for the computer. With the help of a plug-in PLC, the PC becomes an industrial controller.

How does a PLC work?

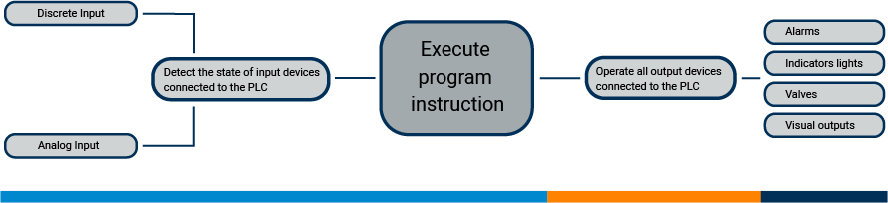

Basic PLC operation goes through these steps:

- Detect the state of input devices connected to the PLC

- There are two types of data inputs: discrete and analog

- Discrete

- Discrete input refers to data when it is in one of two states such as on or off, 1 or 0, open or closed.

- Examples include a push button switch (on/off) or a valve state (open/closed).

- Discrete input refers to data when it is in one of two states such as on or off, 1 or 0, open or closed.

- Analog

- Analog input refers to signals with a range of values, not a simple on/off or open/closed.

- Examples include temperature sensors, pressure sensors, CO2 sensors, and weight scales.

- Analog input refers to signals with a range of values, not a simple on/off or open/closed.

- Discrete

- There are two types of data inputs: discrete and analog

- Execute program instruction based on input.

- Operate all output devices connected to the PLC

- For example: alarms, indicator lights, valves, and/or visual display outputs.

Where is a PLC used?

In everyday life

Many actions from our everyday life are based on a PLC, and we may not even be aware of it.

For example, a PLC can be used to control street lighting to save energy and cut costs while ensuring safety. Street lighting can be one of the largest energy expenses for a city and may account for upwards of 35-45% of a city’s utility budget.

A smart lighting control system controlled by PLCs can reduce street lighting costs as much as 70%. These street lights factor in time of day, data from light sensors, and the presence of pedestrians or cars to determine if they turn on or off.

Other examples include:

- Traffic light circuits

- Digital signage

- Electric windshield wipers and the injection pump on cars

- Automatically controlled shutters

- Heating control systems

- Automatic gate systems

- Elevators and escalators

In industrial manufacturing

Today, industry can no longer do without the electronic, logical based control that PLCs have enabled. They monitor and control automated manufacturing processes to save time, costs and labor. This can include robotic devices, assembly lines and other machine functions. For example, in the food industry, a PLC can be used to detect burnt potato chips and remove them from the assembly line.

- Light sensor identifies dark chips on the conveyor belt (input)

- The logic in the program would use the inputs to identify which blower to activate at the right time.

- The PLC activates blowers to remove burnt chips from the conveyor.

PLC as part of a SCADA system

PLCs are usually part of SCADA solutions. These decentralized systems monitor, visualize and control the entire installation in an industrial environment. The majority of control operations are handled by a PLC or remote terminal unit (RTU).

Data collection begins with the PLC that communicates with the machines. The data is then made visible to the operators by Human Machine Interfaces (HMIs). This allows the operators to interact with the SCADA system software – such as Ignition.

Learn more about SCADA:

Ready to take a deep dive into SCADA? Claim your free copy of the Ultimate Guide to SCADA.

Differences between a PLC and an industrial computer

Industrial computers are the heart of Industry 4.0. Just like PLCs, they receive inputs and produce outputs and are used to control automation. So what is the difference between automation control by a PLC and automation control by an industrial computer?

Interfaces and connections

While a PLC offers a wide variety of I/O options, it is generally more limited. An industrial PC can connect to a wider range of external devices such as displays, drivers, printers, network interface cards and peripherals from different manufacturers. Various I/O and card slots make an industrial PC customizable and expandable as needed. For example, an industrial PC can support wireless or cellular cards, an HMI and/or a vision system. However, an industrial PC will need the appropriate software stack in order to replace a PLC.

Performance and storage

Industrial PCs have a higher processor performance and storage capabilities when compared to PLCs. This can be advantageous for data analysis capabilities, storage (logging) of data, integrating artificial intelligence, machine learning, and overall programming flexibility for complicated scenarios. In addition, an industrial PC can be beneficial in situations where space is limited because workloads can be consolidated and the hardware footprint can be reduced.

Security

PLCs have a very simple operating system, which was developed only for the respective control task. Due to its rudimentary software programming, a hard PLC does not expose security vulnerabilities typically associated with standard consumer operating systems.

In contrast, an industrial PC needs an operating system that enables them to run various applications. You might ask yourself, could the industrial PC be more vulnerable to cyberattacks?

The reality is that industrial PCs in today’s modern age are constructed with significant security related features. In addition, since PCs are ubiquitous, security vulnerabilities and exploitations are usually discovered quickly and prevented. PLCs on the other hand, are updated less frequently, and due to dated technology, this has the capability of yielding an overall less secure implementation.

Durability

Since we are comparing PLCs to industrial computers rather than conventional PCs, there are not any notable differences in terms of resistance to environmental conditions. After all, PLCs, like industrial PCs, were designed to operate in the particularly harsh environments of industrial facilities.

Replacing a PLC with an industrial computer

For small projects, a PLC may be less costly and a good fit. But for projects that might be expanded in the future, an industrial PC may be more suitable and deliver a stronger return on investment (ROI). Ultimately, the specific application determines the choice between a PLC or an IPC.

Not sure what your project needs? Our team of experts is here to help you.

Editor’s Note: Inductive Automation has ended their Ignition Onboard program. Ignition licenses must now be purchased directly through Inductive Automation. While the IGN versions of our solutions are no longer available, our computers remain a great fit for use with Ignition software. Explore our recommended hardware here.

Get the Latest Tech Updates

Subscribe to our newsletters to get updates from OnLogic delivered straight to your inbox. News and insights from our team of experts are just a click away. Hit the button to head to our subscription page.

Share

More Articles

OnLogic Industrial Computers

Discover OnLogic's multitude of industrial computers that will help you to advance your IoT project

Learn more at OnLogic.com

OnLogic Industrial PCs: Designed to last. Built to order. Delivered in days. Visit our online store at OnLogic.com