Setting Up Smart SCADA for Digital Transformation

In the world of modern business, data is everything. Collecting it, analyzing it and — most importantly — acting on it, is the difference between businesses that thrive and those that fail. Whichever steps you take on your individual path toward digital transformation, determining how you’ll manage your data sets a lot of wheels in motion. As we covered recently here on The I/O Hub, Supervisory Control And Data Acquisition (SCADA) is the infrastructure that allows you to take control of your data and harness it to make highly impactful decisions. One of the leaders in smart SCADA is Inductive Automation, who make Ignition, a platform that’s putting users in charge of their data like never before.

A Conversation with Travis Cox of Inductive Automation

We asked Travis Cox, the Co-Director of Sales Engineering at Inductive Automation to answer a few questions about how Ignition users are overcoming the challenges of implementing a modern SCADA solution to make real, business-impacting changes to the way they do business, save time, money and a lot of headaches along the way.

Smart SCADA for Digital Transformation – Where to Start?

OnLogic: Modern SCADA solutions can be intimidating on the surface. For someone looking to start connecting disparate systems in their infrastructure, where would you recommend they start?

Travis Cox: Don’t rip and replace, build a parallel infrastructure first.

A big obstacle to digital transformation is the perception that you need to rip and replace your legacy system. It’s intimidating to think about having to use a whole new system, because that would affect productivity and disrupt business as usual. There are hundreds of millions of proprietary legacy PLCs and devices that are still in use. Upgrading all of them would be incredibly cost-prohibitive. You can’t just switch to a new technology overnight; that would result in a catastrophic failure and loss of revenue.

We can solve this by taking a different approach, which is to build a parallel infrastructure alongside your existing installation, using software. It is much easier to get started with software than hardware. You can gradually transition devices from your old system to your new IIoT infrastructure. The gradual approach gives you time to test out the new system and make sure it is stable before you make a complete infrastructure transition. That also allows you to achieve ROI wins as you go along solving problems in the system. As you remove manual work, get rid of paper and whiteboards, gather and centralize more data, and add things like history, alarms, and reporting, you’ll see returns for each of those improvements.

Another important point is that you should look for a platform you can build on. The usual approach has been to add coding on top of operating systems, but the better approach is to build applications on top of platforms. That’s because platforms are open, standards-based, scalable, extensible, and future-proof, compared to conventional software products. It is very important to choose platforms that have an unlimited licensing model and that can communicate to disparate systems, allowing you to bring all your data together and make it available to whoever needs it.

Key Communication Protocols for Digital Transformation

OnLogic: Are there key communication protocols that are emerging as go-to options when it comes to this type of digital transformation?

Travis Cox: Connect your devices directly to your infrastructure, not just your applications.

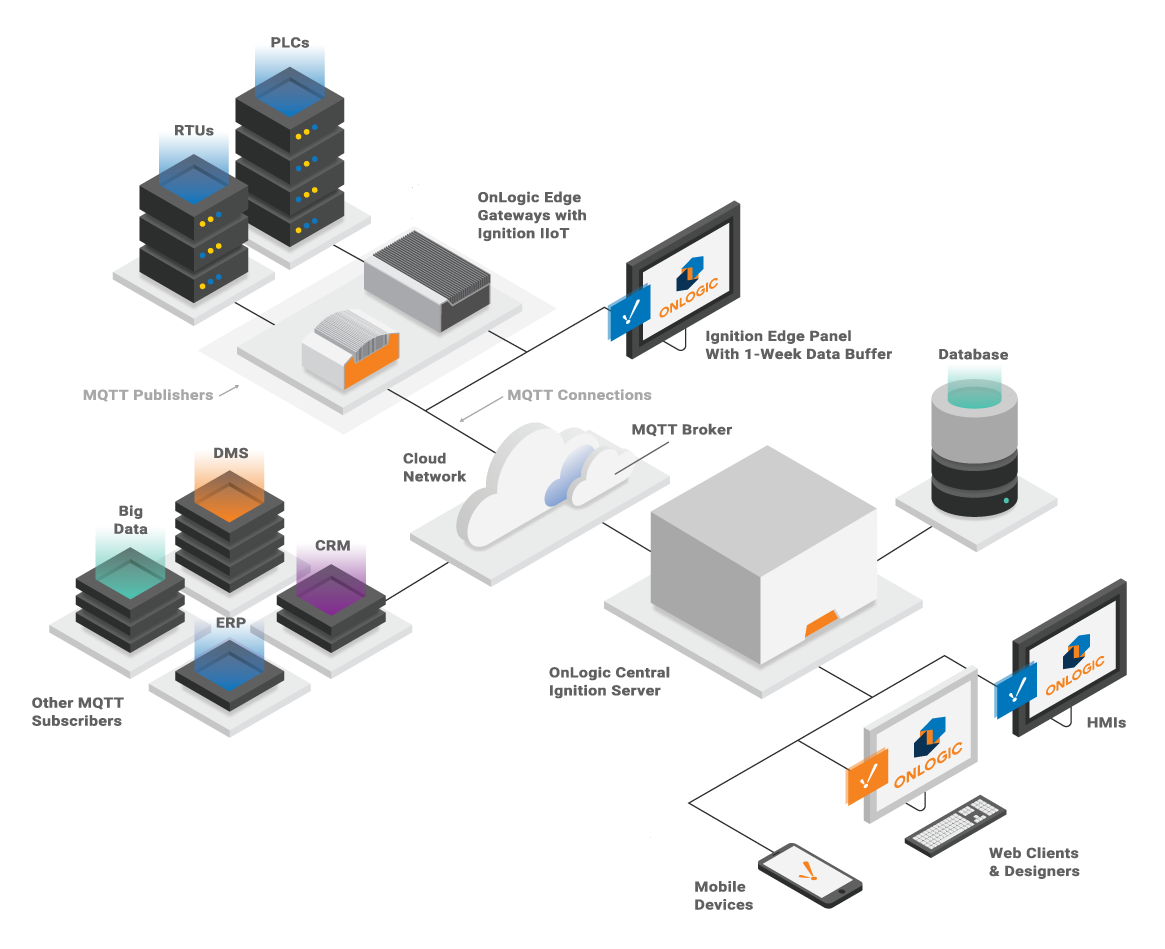

The operational world is extremely complex, involving hundreds of different protocols, communication mediums, and legacy devices. The reality of digital transformation is this: it must be implemented from the bottom up, with OT on board first. It requires a new mentality or mind shift towards keeping systems open, interoperable, and secure. The journey starts with the operational infrastructure and creating a migration strategy that implements the digital transformation but also meets all the OT requirements. It boils down to a single, crucial concept: an architecture change. We need to stop connecting devices to applications with protocols and, instead, connect devices to infrastructure. At the same time, we need to provide a superior OT solution that meets the needs of operators that is plug-and-play, reliable, and scalable.

MQTT provides several benefits:

- Open standard/interoperable (OASIS standard & Eclipse open standard [TAHU])

- Decouples devices from applications

- Reports by exception

- Requires little bandwidth

- TLS security

- Remote-originated connection (outbound only; no inbound firewall rules)

- Stateful awareness

- Single source of truth

- Auto-discovery of tags

- Data buffering (store & forward)

- Plug-and-play functionality

In summary, MQTT is the de facto standard for IIoT communication.

Potential Roadblocks in a Smart SCADA Project

OnLogic: Are there other roadblocks that you would recommend watching out for when it comes to smart SCADA projects?

Travis Cox: Every project is unique, but look out for these potential challenges:

Fear of change

One roadblock isn’t technology-based, it’s a human problem. Every organization has people who are resistant to change. They’ve gotten used to doing things the same way for years. Or they might think adopting a new solution is too risky. Or they might be worried about the learning curve. Or they might think it will be very difficult and time-consuming to implement new solutions. Whatever their reason might be, they often stop digital-transformation initiatives from getting off the ground. In terms of people, you might need to look around the organization for a new champion who is able to help push your initiative forward. In terms of technology, one way to get around these objections is to show the value using trial software.

Cost prohibitive licencing structures

Another roadblock we run into is the cost of licensing and the struggle to realize ROI. You need to ensure the new systems you put in place have unlimited licensing models and allow you to achieve ROI as you modernize. This comes down to using systems that take advantage of the latest and greatest technology and tried-and-true standards.

A disconnect between OT and IT

The gap between the OT and IT departments is also a roadblock. They tend to work in siloed environments and to speak different languages and have different responsibilities. We can bring the two sides closer together if OT uses tools & technologies that IT understands. That includes open standards like MQTT, OPC UA, SQL databases, SOAP and REST, HTML5, and CSS.

Information silos

Here’s another big roadblock: the challenge of getting data out to more people in the organization, especially on the business side. That creates a big disconnect between the people on the plant floor or in the field and the people in the office. The solution is to get more data out by adding mobile-first applications, ideally using native HTML5. A well-designed app on a smartphone or smart device can let you see your entire system at a glance, or a chart or dashboard with data that’s relevant to your specific job. Mobile solutions will make more data visible and accessible to more people, and that is going to empower them to respond to problems more quickly and make better decisions. Of course, this comes with challenges such as providing Wi-Fi in the plant or making applications publicly available.

Security concerns

Another challenge is the delicate balance between increasing the accessibility to data without compromising security. The solution for this is to use modern cybersecurity practices such as encryption protocols like SSL and TLS, using federated identity providers that support two-factor authentication and single-sign-on (SSO), and the ability to leverage security infrastructures such as DMZs.

Uncertainty about how to leverage the cloud

The last roadblock is the question of how to work with the cloud and how to seize the opportunities that are there. A good solution is one that is compatible with cloud providers and allows you to fully take advantage of your data with things like analytics and machine learning, or that can utilize the cloud for more scalability.

Leveraging Ignition – Smart SCADA Use Cases

OnLogic: What are some of the use cases, environments, or applications that you see as having the most potential to benefit from implementing a smart SCADA platform like Ignition?

Travis Cox: There are four key use cases that really leverage Ignition’s capabilities:

- Using Ignition’s unlimited licensing model and powerful modules to solve challenges around the organization. As you remove manual work, get rid of paper and whiteboards, gather and centralize more data, and add things like history, alarms, and reporting, you’ll see returns for each of those improvements.

- Getting data to more people using Ignition Perspective, native HTML5 clients. Simply using modern browsers allows access to the data from anywhere. You also get the advantage of leveraging mobile device features like GPS, accelerometer, camera, barcode scanner, NFC, Bluetooth, and touch gestures.

- Leverage MQTT to decouple devices from applications and provide a more scalable architecture, often by leveraging edge devices for store & forward and local functionality. This is especially important for remote systems, such as in oil and gas, water/wastewater, and energy.

- Leveraging the cloud in 2 ways:

- Deploying Ignition to the cloud for easier maintenance and scalability. This allows users to make applications and data more available.

- Injecting data to take advantage of higher-level capabilities like advanced analytics, business intelligence & machine learning.

Leveraging Ignition HMI

Onlogic: We often hear that pairing the Ignition HMI software with rugged Panel PCs is a more cost-effective approach and offers more features than legacy SCADA solutions. What makes Ignition HMI a better solution?

Travis Cox: Ignition’s HMI paired with a rugged Panel PC provides the functionality of traditional HMIs plus a lot more.

While HMIs can certainly run independently, they are not isolated or siloed off. They provide the ability to have local functionality and store & forward that integrates natively into a centralized system. You get the added benefit of being able to centrally manage the HMIs for health and diagnostics, disaster recovery, and remote upgrades. If a unit dies, it is extremely easy to get a new one in place vs. traditional HMIs. They are also geared towards Industry 4.0 because they can bridge the gap between legacy device protocols and standards like OPC-UA and MQTT.

Benefits of Ignition Onboard Program

OnLogic: Can you tell us a bit more about the Ignition Onboard program?

Inductive Automation has partnered with trusted hardware providers, such as OnLogic, to deliver select devices with Ignition Edge by Inductive Automation® installed and configured by the manufacturer. This sets you up for effortless installation and deployment of your new solution. There are several benefits of using Ignition Edge on an Onboard device:

- You can skip the installation and save time because Ignition Onboard devices come with Ignition or Ignition Edge already installed.

- Plug-and-play functionality; because Ignition is open and interoperable, it works with just about every system.

- Ignition uses MQTT to instantly subscribe to your industrial data, making the device IIoT-ready.

- All Ignition Onboard devices are run through the same rigorous benchmarking process. Customers can compare device performance side-by-side before they buy.

- Ignition installations have been optimized by the hardware manufacturer for maximum performance.

- All Ignition Onboard devices have been tested and validated by Inductive Automation engineers to ensure compatibility.

By combining the industry’s leading software with the best hardware, the Ignition Onboard program makes implementing digital transformation that much easier.

Ready to learn more about Ignition industrial automation solutions? Browse our Ignition Onboard solutions and contact our technical sales team today!

Editor’s Note: Inductive Automation has ended their Ignition Onboard program. Ignition licenses must now be purchased directly through Inductive Automation. While the IGN versions of our solutions are no longer available, our computers remain a great fit for use with Ignition software. Explore our recommended hardware here.

Get the Latest Tech Updates

Subscribe to our newsletters to get updates from OnLogic delivered straight to your inbox. News and insights from our team of experts are just a click away. Hit the button to head to our subscription page.

Share

More Articles

OnLogic Industrial Computers

Discover OnLogic's multitude of industrial computers that will help you to advance your IoT project

Learn more at OnLogic.com

OnLogic Industrial PCs: Designed to last. Built to order. Delivered in days. Visit our online store at OnLogic.com